Overview

OEG’s subsea team has expanded our dimensional control survey service offering to Eastern Asia, undertaking multiple surveys in spring 2024. This follows on from increased growth in our services offered to the global offshore energy industry.

Challenges

The survey works had to fit around dockyard movements and cable loading, limiting the available movements of the survey team.

A particular area of challenge onboard the Connector was to survey the Pliant DAMS. Due to its location cantilevered over the cable chutes at the aft end of the vessel, visibility from onboard was very restricted. The client needed to understand the orientation of the DAMS to allow for accurate calculation of cable exit angles from the vessel.

Workscope

Carrying out full dimensional control and calibration surveys for two vessels located in Eastern Asia before undertaking offshore works.

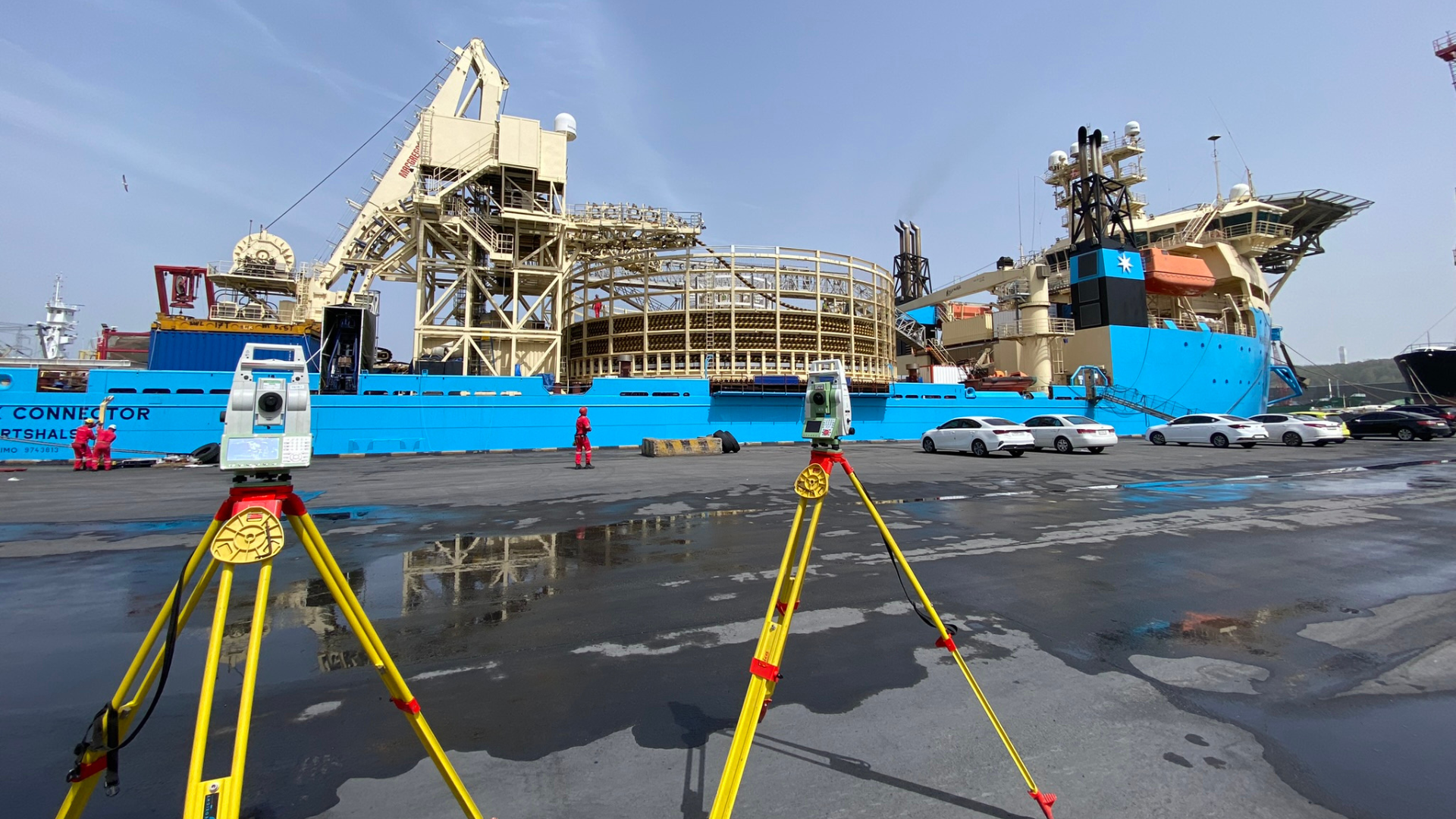

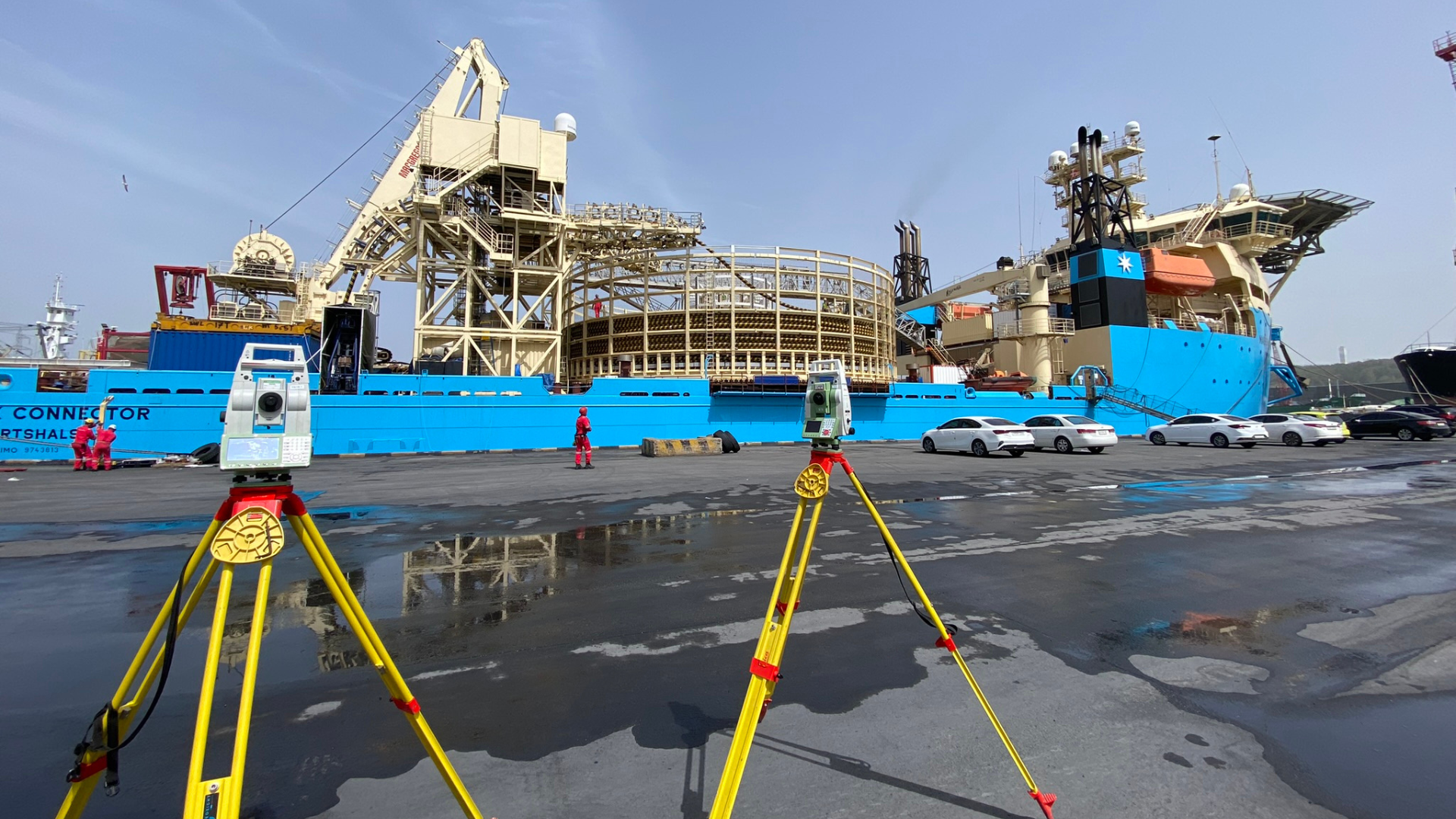

The vessels surveyed were the Maersk Connecter, a cable lay vessel located in Donghae, South Korea, and the Boka Tiamat, a construction support vessel located in Taichung, Taiwan.

Solution

The Maersk Connector, a cable lay vessel, was in port taking on cable and required a full dimensional control and calibration survey before heading offshore. Initial measurements were taken to define the Vessel Reference Frame and to then establish the offsets for over 80 individual sensor and nodes located around the vessel. Additionally, the vessel WROV, mobilised for bathymetric survey, required a full survey and calibration.

The Boka Tiamat, a construction support vessel due to be deployed on the same project to provide trenching and survey capabilities, required multiple independent surveys to take place simultaneously – the vessel, ROV, trencher and an over-the-side pole all required separate reference frame surveys before being unified into one survey system.

Once all offsets had been collected and processed, the vessels and ROVs went through a calibration process to align the Heading and Attitude sensors with their respective reference frames. The team made use of Leica Smartnet PPP GNSS correction service to enable accurate ground control points without any geographic or infrastructure limitations.

As part of our quality assurance process, the survey team ran through a full validation process, checking all values had been entered correctly and that the vessel survey systems were able to compute nodes around the vessel within the required accuracy.

The overall process took under three days per vessel, from initial acquisition to delivery of preliminary results enabling the vessel to sail and commence work.

OEG’s focus on professionalism ensured full client satisfaction and reassurance to the vessel survey teams that their systems are fully functional and capable of providing accurate positioning.

.png?width=3600&height=1600&name=OEG%20-%20Vessel%20geometry%20software%20-%20GEOBASE%20-%203600%20x%201600px%20(1).png)