Temporary power

- Services

- Topside services

- Offshore equipment solutions

- Temporary power

Essential temporary power solutions

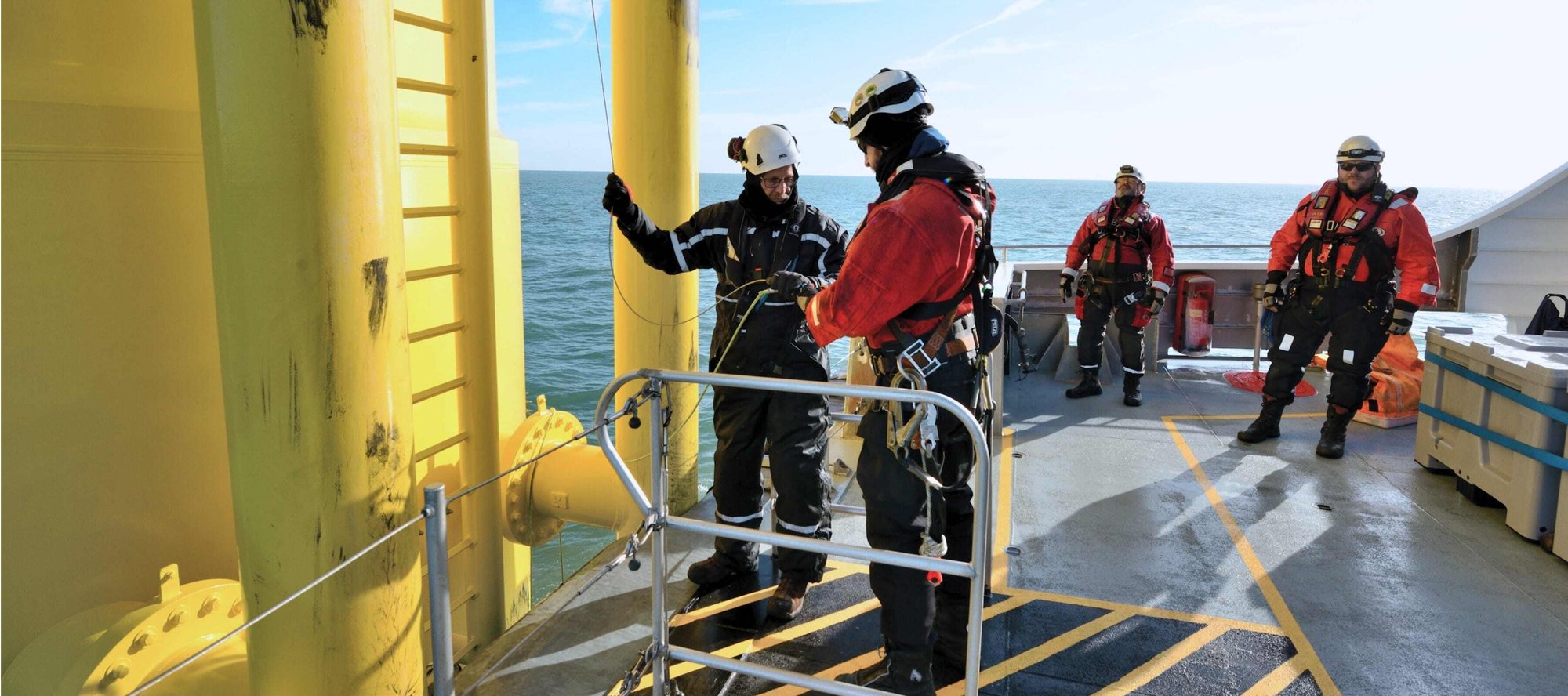

Following the acquisition of Manor Renewable Energy (MRE) by OEG in 2023, OEG has enhanced its capabilities in delivering essential temporary power solutions offshore during critical phases of global projects.

With our bespoke temporary power solutions complemented by our strong technical management and purpose-built CTV fleet, we are well positioned to deliver a turnkey product and meet the sector’s growing needs.

Whether your requirement is for the construction phase or O&M support, we can supply tried and tested and innovative temporary power solutions.

Experts in our field

Experience

Highly experienced on and offshore management team, technicians and crew - with over 16 offshore projects undertaken since 2013. We have highly experienced personnel throughout the disciplines, both on and offshore. The knowledge and lessons learnt are cascaded into each and every project and high levels of safety are implemented from the project kick-off.

Experience

Highly experienced on and offshore management team, technicians and crew - with over 16 offshore projects undertaken since 2013. We have highly experienced personnel throughout the disciplines, both on and offshore. The knowledge and lessons learnt are cascaded into each and every project and high levels of safety are implemented from the project kick-off.

Highly experienced on and offshore management team, technicians and crew - with over 16 offshore projects undertaken since 2013. We have highly experienced personnel throughout the disciplines, both on and offshore. The knowledge and lessons learnt are cascaded into each and every project and high levels of safety are implemented from the project kick-off.

Design

Generators designed to interface correctly with the transition piece and turbine - with space often at a premium on the transition piece platform. We have the provision to both design and fabricate customised solutions. As a general rule, our solutions are of a modular set-up requiring one lift on (from the installation vessel) and several lifts off (utilising the TP crane); often the most cost-effective solution for the project.

Design

Generators designed to interface correctly with the transition piece and turbine - with space often at a premium on the transition piece platform. We have the provision to both design and fabricate customised solutions. As a general rule, our solutions are of a modular set-up requiring one lift on (from the installation vessel) and several lifts off (utilising the TP crane); often the most cost-effective solution for the project.

Generators designed to interface correctly with the transition piece and turbine - with space often at a premium on the transition piece platform. We have the provision to both design and fabricate customised solutions. As a general rule, our solutions are of a modular set-up requiring one lift on (from the installation vessel) and several lifts off (utilising the TP crane); often the most cost-effective solution for the project.

Endurance

Fuel tanks with as large as practical capacity to increase endurance. When calculating the fuel consumption we look at the distance offshore, time of year with associated weather conditions, and availability of refuelling vessels. Recent projects have shown that a minimum of 2000 litres provides a stable platform to ensure continual generator availability. To achieve that we often fabricate tanks in-house to allow the modular set-up with a minimised footprint.

Endurance

Fuel tanks with as large as practical capacity to increase endurance. When calculating the fuel consumption we look at the distance offshore, time of year with associated weather conditions, and availability of refuelling vessels. Recent projects have shown that a minimum of 2000 litres provides a stable platform to ensure continual generator availability. To achieve that we often fabricate tanks in-house to allow the modular set-up with a minimised footprint.

Fuel tanks with as large as practical capacity to increase endurance. When calculating the fuel consumption we look at the distance offshore, time of year with associated weather conditions, and availability of refuelling vessels. Recent projects have shown that a minimum of 2000 litres provides a stable platform to ensure continual generator availability. To achieve that we often fabricate tanks in-house to allow the modular set-up with a minimised footprint.

Installation

Aims to install onto transition piece at the staging port to minimise offshore works. We have undertaken projects where the installation of the generator is undertaken whilst the transition piece is sited in the staging port; this allows full testing and commissioning prior to heading offshore, whilst also minimising any costly offshore lifts from the installation vessel.

Installation

Aims to install onto transition piece at the staging port to minimise offshore works. We have undertaken projects where the installation of the generator is undertaken whilst the transition piece is sited in the staging port; this allows full testing and commissioning prior to heading offshore, whilst also minimising any costly offshore lifts from the installation vessel.

Aims to install onto transition piece at the staging port to minimise offshore works. We have undertaken projects where the installation of the generator is undertaken whilst the transition piece is sited in the staging port; this allows full testing and commissioning prior to heading offshore, whilst also minimising any costly offshore lifts from the installation vessel.

Fuel capacity

State of the art refuelling vessels with an onboard fuel capacity of over 40 Tonnes. Whether it be our own vessels or similar tonnage, we provide only vessels that have the sufficient onboard fuel capacity to allow multiple tanks to be refilled during a single offshore trip; in tandem with this capacity, we provide onboard accommodation for all technicians to give sufficient endurance on far offshore windfarms.

Fuel capacity

State of the art refuelling vessels with an onboard fuel capacity of over 40 Tonnes. Whether it be our own vessels or similar tonnage, we provide only vessels that have the sufficient onboard fuel capacity to allow multiple tanks to be refilled during a single offshore trip; in tandem with this capacity, we provide onboard accommodation for all technicians to give sufficient endurance on far offshore windfarms.

State of the art refuelling vessels with an onboard fuel capacity of over 40 Tonnes. Whether it be our own vessels or similar tonnage, we provide only vessels that have the sufficient onboard fuel capacity to allow multiple tanks to be refilled during a single offshore trip; in tandem with this capacity, we provide onboard accommodation for all technicians to give sufficient endurance on far offshore windfarms.

Decommissioning

Contemporary modular design for ease of decommissioning on project completion. Our 2000 and 3000 litre models break down into three and five individual components respectively; this then reduces the largest lift to under 1.5 tonnes and therefore into the capability of the transition piece crane; this crane combined with the ‘stern to’ capability of the Manor Venture allows for a cost-effective demobilisation.

Decommissioning

Contemporary modular design for ease of decommissioning on project completion. Our 2000 and 3000 litre models break down into three and five individual components respectively; this then reduces the largest lift to under 1.5 tonnes and therefore into the capability of the transition piece crane; this crane combined with the ‘stern to’ capability of the Manor Venture allows for a cost-effective demobilisation.

Contemporary modular design for ease of decommissioning on project completion. Our 2000 and 3000 litre models break down into three and five individual components respectively; this then reduces the largest lift to under 1.5 tonnes and therefore into the capability of the transition piece crane; this crane combined with the ‘stern to’ capability of the Manor Venture allows for a cost-effective demobilisation.

Temporary power pods

Whether your requirement is for the construction phase or to support operations & maintenance downtime, we can supply various tried and tested temporary power solutions for the offshore wind sector. These can also be tailored to suit unique requirements.

.png?width=1460&height=830&name=OEG%20-%20Marine%20logistics%20services%20-%20Furioso%20vessel%20-%201460%20x%20830%20(1).png)

Supported by our fleet of crew transfer vessels

We currently own and globally operate 15 multi-purpose CTV offshore vessels. All of these are located across the globe supporting offshore wind construction and operation and maintenance activities.

Featured Case Studies

Established track record delivering successful projects for our customers

Why choose us

At OEG, we are market-leaders in the provision of temporary power solutions and our mechanical and electrical engineering teams have extensive experience with all aspects of power generation.

We are capable of dealing with the many and varied challenges encountered on offshore wind projects globally; we bring together the expertise and experience of our teams of marine and engineering professionals to assist us with the growing industry demand for efficient and reliable offshore solutions.

Want to find out more?

Our team of technical experts are here to support you.

.png)